CONDUCTOR CASING / WELLHEAD WELDING Wilson's Pipe Fabrication

Conductor Casing. "Conductor casing" means a casing string which is often set and cemented at a shallow depth to support and protect the top of the borehole from erosion while circulating and drilling the surface casing hole. Source: Corporation Commission, Oil and Gas Conservation, Oklahoma Administrative Code 165:10, February 2013.

Conductor Casing at an Angle Part 2 EllingsonDTD

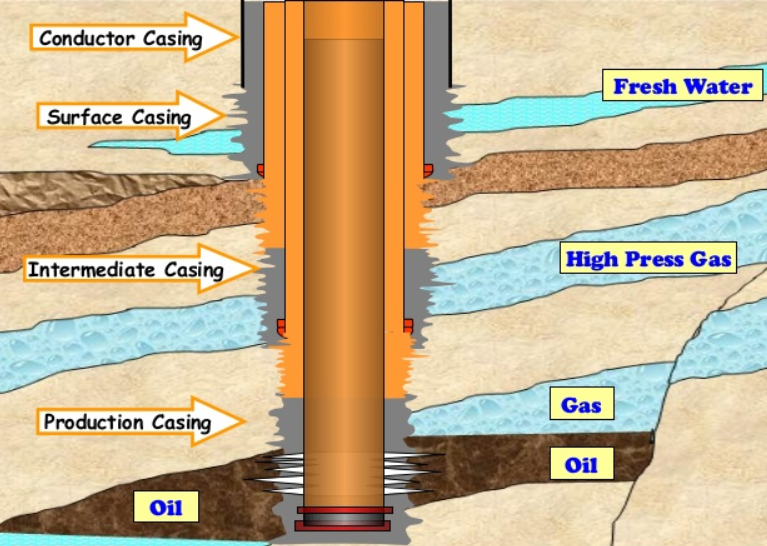

Conductor casing, surface casing, intermediate casing, and production casing are generally the four casing types used in an oil and gas well, with the following running sequence, application functions, and cement planning, respectively: • Conductor casing is the first casing, normally in size of 16″ ~ 26″ -

CONDUCTOR CASING / WELLHEAD WELDING Wilson's Pipe Fabrication

Drive pipe or conductor casing. The first string run or placed in the well is usually the drive pipe, or conductor casing. Depths range from 40 to 300 ft. In soft-rock areas such as southern Louisiana or most offshore environments, the pipe is hammered into the ground with a large diesel hammer. Hard-rock areas require that a large-diameter.

CONDUCTOR CASING / WELLHEAD WELDING Wilson's Pipe Fabrication

The casing trip-in program of offshore drilling operation consists of oil-gas well conductor (surface conductor, riser, etc.), surface casing, intermediate casing, etc. Production casings such as tubing should also be tripped in the development well. Oil-gas conductor is the significant closed channel that constitutes platform of subsea oil-gas.

Conductor OIL AND GAS SERVICES

Conductor Casing. In the offshore drilling industry, the conductor pipe is set in the seabed, and is a key structural foundation for the subsea wellhead. When drilling an offshore well, a marine riser is connected to the well, and this is subjected to large environmental forces such as current and waves which are transferred to the conductor.

Conductor Casing for Oil and Gas Wells ZETAS

Installing conductor casing Casing is pipe usually larger in diameter and longer than drill pipe and is used to line the hole. Casing operations occur periodically throughout the drilling process starting with the surface casing, intermediate casing, and ending with production string which takes place during well completion.

Dual Rotary Wellbore Casing , HWT BW NW Conductor Casing Drilling

Casing (borehole) Casing is a large diameter pipe that is assembled and inserted into a recently drilled section of a borehole. Similar to the bones of a spine protecting the spinal cord, casing is set inside the drilled borehole to protect and support the wellstream. The lower portion (and sometimes the entirety) is typically held in place.

Conductor Casing Pipe Specs, Installation For Oil & Gas Drilling Manual

Other articles where conductor casing is discussed: fracking: Horizontal drilling:.inches) in diameter, called the conductor casing, that is cemented into place. From there the borehole is drilled straight down, passing through numerous rock layers that may include contaminable freshwater aquifers used for private wells or municipal water supply.

CONDUCTOR CASING / WELLHEAD WELDING Wilson's Pipe Fabrication

Conductor Casing. Conductor casing is the first string set below the structural casing (i.e., drive pipe or marine conductor run to protect loose near-surface formations and to enable circulation of drilling fluid). The conductor isolates unconsolidated formations and water sands and protects against shallow gas. This is usually the string onto.

Repair of Conductor Casings using Engineered Grouted Clamps NAUTEC

The conductor casing is the first string run in the well and its depth range is 40 to 300 ft. In soft formation areas or offshore environment, the conductor pipe is hammered down by a large pipe hammer. In hard rock areas, driving the casing is not doable therefore a larger hole must be drilled to landing depth before running and cement this.

Casing Specifications Production Technology

The conductor casing was planned to be set between a minimum of 750 m and a maximum of 1000 m to prevent potential loss circulation observed in two offset wells. The maximum depth for setting casing was limited to 1100 m due to the medium risk of shallow gas. The conductor casing utilized was 20" SL-BOSS 133ppf X-56 which came up with a.

Conductor & casing cold cutting Acteon

Conductor Casing: The first casing installed in the well is called the conductor casing, as shown in the figure below. Onshore this is a short segment usually around 60 ft (20 m) long. The conductor isolates unconsolidated formations and water sands and protects against shallow gas. This is usually the string onto which the casing head is.

Introduction to Casing Drilling Course

A casing of smaller diameter (13 \( 3/8. \) in. or 339 mm), called a surface casing, is placed inside the conductor casing and cemented in place to isolate freshwater aquifers that may be present near the surface. An intermediate casing may be required for a deep well in which a well blowout induced by formation pore pressure or hydraulic.

CONDUCTOR CASING / WELLHEAD WELDING Wilson's Pipe Fabrication

The conductor pipe runs from the seafloor/surface to relatively shallow depths, providing a conduit to allow circulation of drilling fluid and case off unconsolidated formations. It is the first string we use to support well control equipment, typically a drilling diverter. A standard size for the conductor casing pipe is 24″, 26″, or 30″.

Conductor Casing at an Angle EllingsonDTD

The conductor pipe is cemented back to the surface. It is either used to support subsequent casing and wellhead equipment or the pipe is cut off at the surface after setting the surface casing. Where shallow water or gas flow is expected, the conductor pipe is fitted with a diverter system above the flowline outlet.

Carmel Valley, CA welding up a conductor casing YouTube

Set the Conductor Casing: Prior to the arrival of the drilling rig, an Auger Unit (in hard rock regions) will drill a large diameter hole capable of accommodating 18 in. to 36 in. conductor casing (see Figure 9.16). In soft rock regions or at offshore locations, a diesel hammer may be used to hammer the conductor casing into place.