What is Lathe Machine? Types of Lathe Machine & Their Uses Guide] Engineering Learn

As mentioned earlier, a 13 x 35.25 CNC lathe from CNC Masters with all the bells and whistles you'll need to get started is priced at $10,695. Small CNC mini-lathes are $2,000 to $9,000, while most two-axis models range from $15,000 to $50,000. Large production lathes can go as high as $300,000 or more.

LATHE MACHINE Buy Lathe machine CZ1340G1, Lathe machine CZ1440G1, Bench lathe CZ1340G/1

Mesin Bubut CNC (CNC Lathe Machine) adalah mesin perkakas yang dioperasikan dengan sistem Computer Numerical Control (CNC) dan dilengkapi dengan petunjuk desain yang presisi. Mesin Bubut CNC merupakan mesin perkakas yang material atau benda kerjanya dijepit dan diputar oleh spindel utama, sedangkan pahat pemotong yang mengerjakan material.

What is Metal Lathe Machine? Use, Definition, Operations, Parts, Diagram

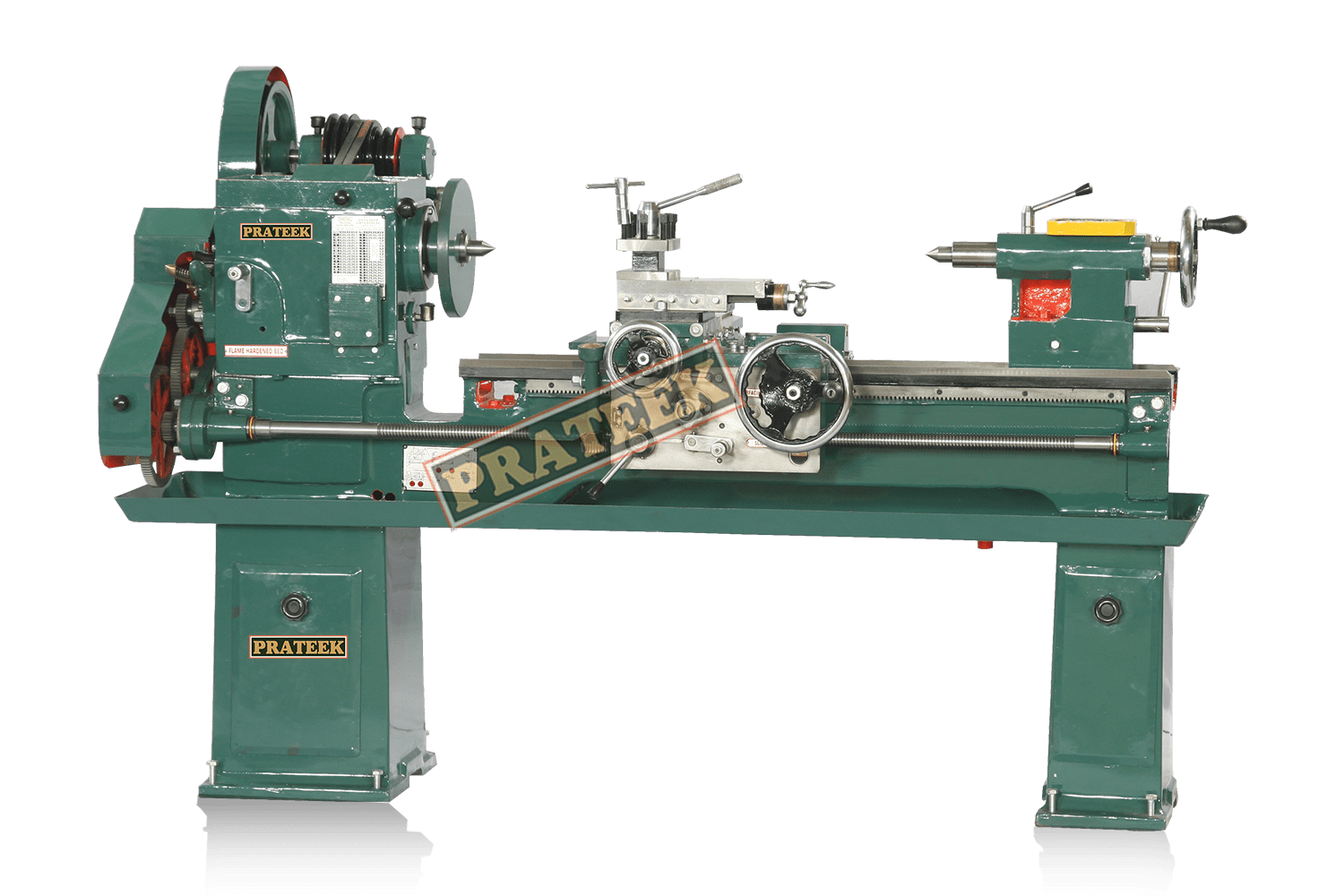

The rapid development of all types of machine tools. In the 19th century, with the growth of various industries, the demand for various types of machine tools increased. In 1817, Roberts created the gantry lathe, and in 1818, Whitney from the United States invented the world's first general-purpose milling machine. Roberts gantry lathe.

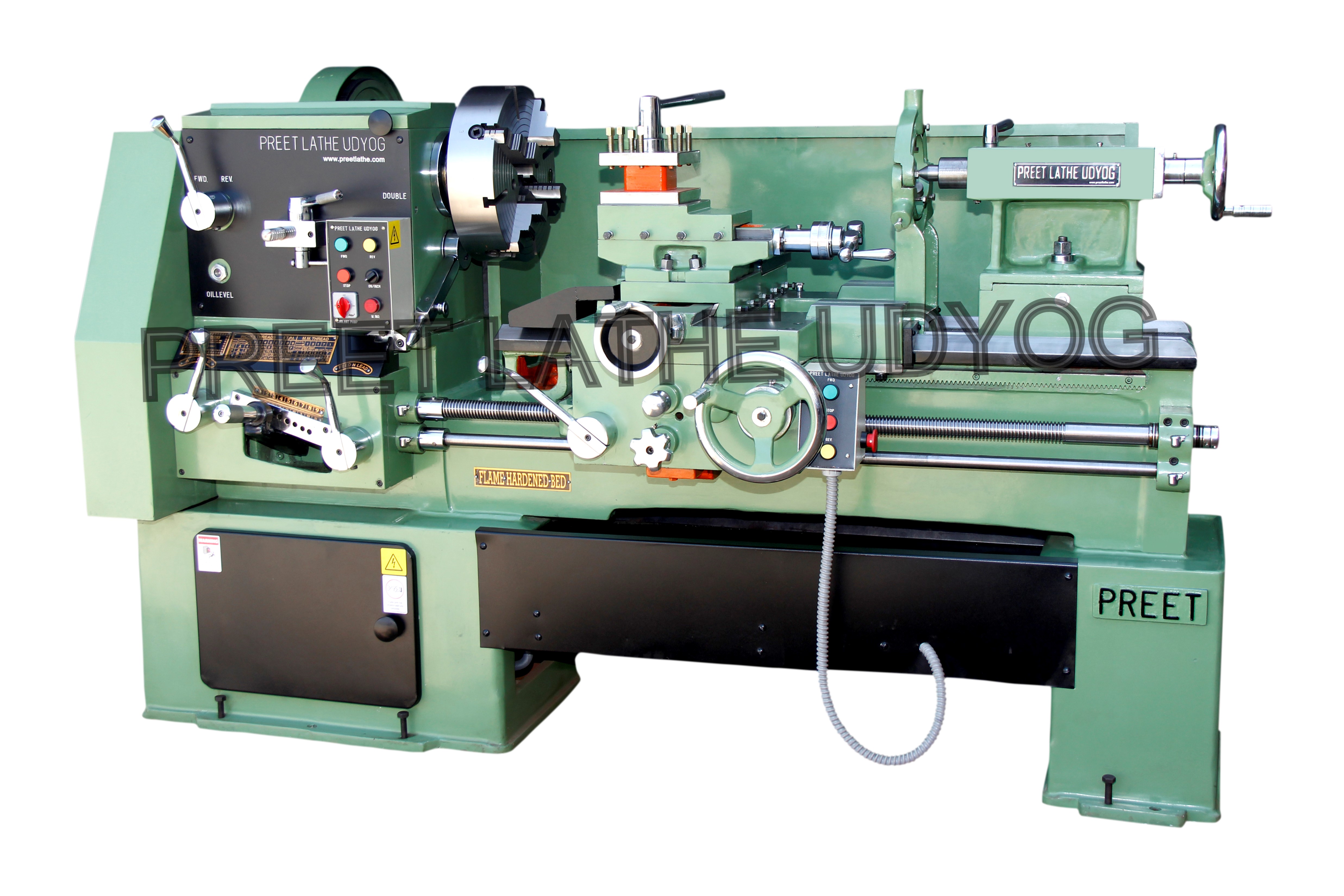

Lathe Machine in Batala Conventional Lathe Machine

A lathe is a machine tool that rotates a cylindrical material and cuts off unnecessary parts by putting a tool bit (cutting tool) against it. Besides turning using a basic right-cut tool, other lathe methods include drilling, boring, grooving, and threading. An NC lathe by comparison can selectively use several dozen types of tool bits in a.

Lathe machine

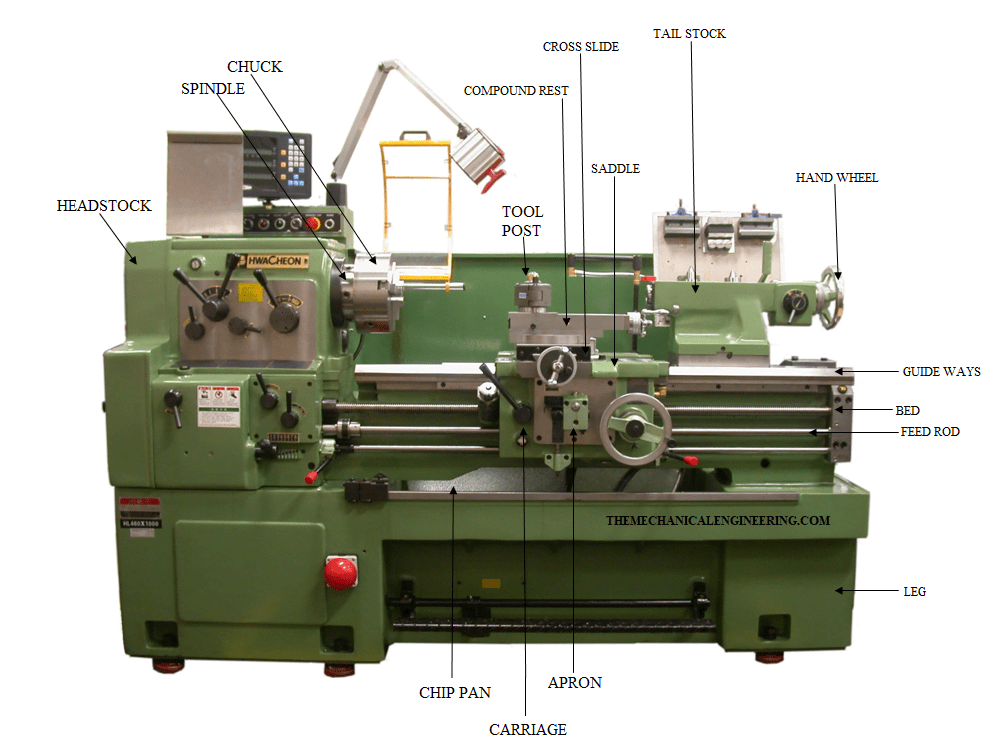

INTRODUCTION: In the Mechanical Engineering field Lathe machine plays an important role in Manufacturing. In this article, I am going to discuss the Lathe machine in detail. A lathe is a machine tool which is used to remove unwanted metals from the work piece to give desired shape and size.; Lathe machine is one of the most important machine tools which is used in the metalworking industry.

HEAVY DUTY ALL GEAR LATHE MACHINE 7 / 9 / 12 / 14 Feet Swing Dia 500 mm With 80 mm / 3 Inch

lathe, machine tool that performs turning operations in which unwanted material is removed from a workpiece rotated against a cutting tool.. The lathe is one of the oldest and most important machine tools. Wood lathes were in use in France as early as 1569. During the Industrial Revolution in England the machine was adapted for metal cutting. The rotating horizontal spindle to which the.

Medium duty lathe machine

Definition. A lathe is a machine, which removes the metal from a piece of work to the required shape and size. Lathe is one of the most important machine tools in the metal working industry. A lathe operates on the principle of a rotating workpiece and a fixed cutting tool. The cutting tool is feed into the workpiece, which rotates about its.

Lathe Machine Lathe Machine Manufacturer Blog Alfa Metal Machinery

3. Centre Lathe or Engine Lathe. Your Centre Lathe has all the parts described above and you can turn outside-diameter, bore, facing, centering, taper turning, threading, knurling etc. You can mount drills, taps, and reamers on the tailstock and do drilling, reaming, and tapping. The rigid construction and spindle speeds allow you to give heavy cuts.

Lathe Machine Definition, Parts, Types, Operation, Specification, Advantages, Application

Products which can be made from lathe machine are: A variety of products can be made from the lathe machine. Some of them are: Nuts, bolts, piston, Ram, pump part, electric motor parts, sleeves, Air craft parts, gun barrels, candlesticks, train parts, cue sticks, wooden bowls, baseball bat, crankshaft and many more things..

Lathe Machine

Lathe Machine is used in all the engineering applications and also in the college Workshops. Lathe machine is used to perform all the basic operations such as drilling, cutting, tapping, turning, etc. with the help of different tools placed in the work environment. Here in this article, I am going to discuss the Lathe Machine along with its Definition, Parts, Types, Working Principle.

Lathe Machine demonstration YouTube

Lathe machine operations performed by holding the work by a chuck or a faceplate or an angle plate are: Drilling: Drilling is the operation of producing a cylindrical hole in a workpiece. It is done by a rotating tool, the rotating side of the cutter, known as a drilling drill. In this operation, The workpiece is revolving in a chuck or a.

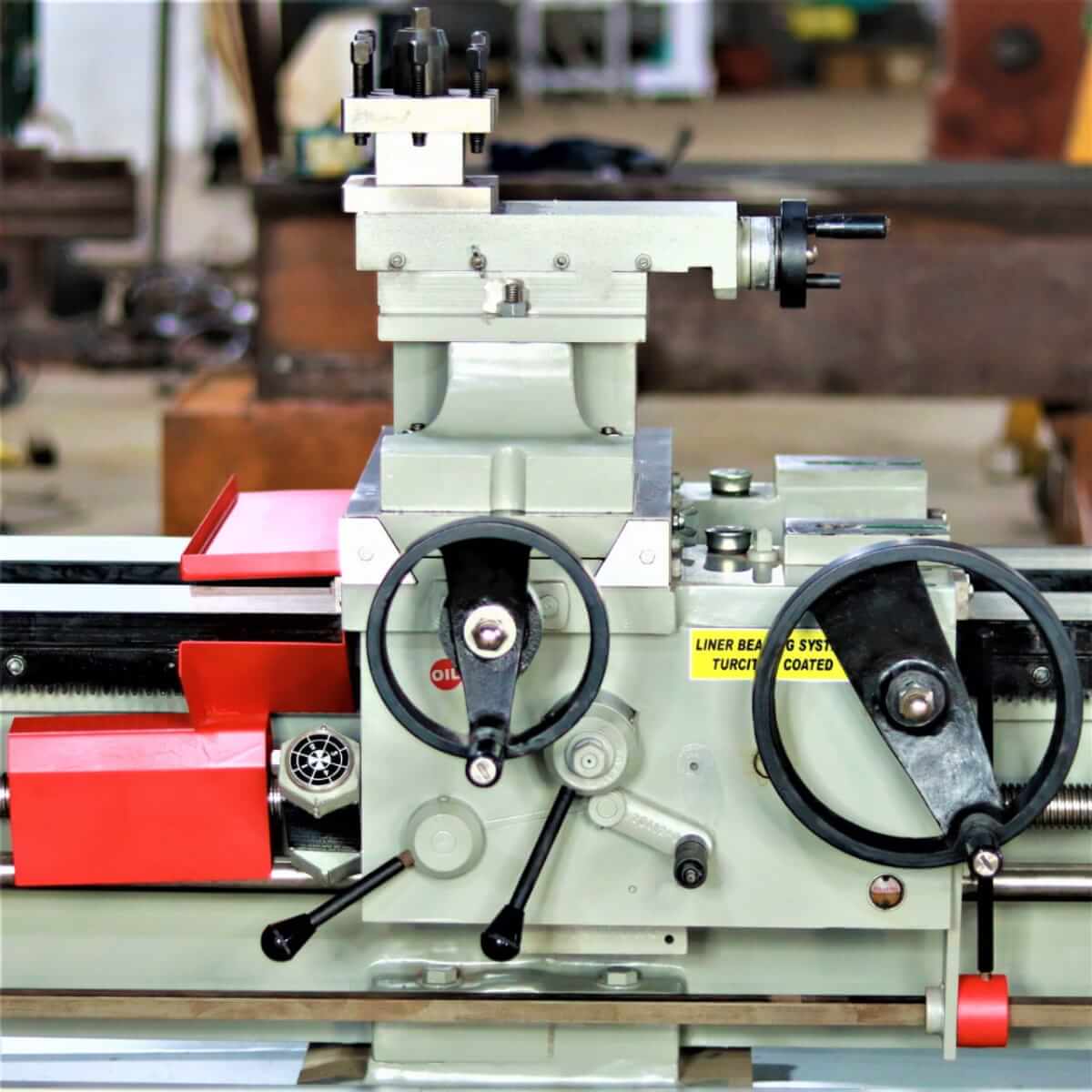

Different parts of lathe machine and their functions ENGINEERING APPLICATIONS

Three-jaw chucks are often used on lathe machines and indexing heads. All of the jaws of three-jaw chucks are fitted into a scroll plate, which makes the 3 jaws can move simultaneously when adjusted by the chuck wrench, then grasps the lathe part very quickly and accurately. The jaws can be made in different sizes.

Extra Heavy Duty Lathe Machine, Horizontal Lathe, 10002000 rpm, ID 19938984230

Mesin bubut (lathe machine) adalah sebuah mesin yang memutar benda kerja pada suatu sumbu rotasi untuk melakukan berbagai operasi seperti pemotongan, pengamplasan, knurling, pengeboran, facing, turning, dan banyak operasi lainnya. Mesin bubut umumnya dirancang untuk memotong material logam dan tersedia dalam jenis manual dan otomatis.

Types of Lathe Machines & Their Uses Guide] PDF

A lathe machine operates on a simple principle, but it has many complex moving parts. Most lathes contain a headstock, tailstock, spindle, motor, chuck, and an assortment of cutting tools. First, the workpiece is fastened to the chuck. This is the part of the machine that holds the piece in place.

Universal Lathe Machine

A lathe is a machine tool that rotates a workpiece around an axis of rotation to perform various operations such as cutting, grinding, knurling, drilling, deforming, facing, and turning with tools applied to the workpiece to create an object with symmetry around this axis. Lathes are used in woodturning, metalworking, metal spinning, thermal.

Lathe Machine 12ft 3600 mm Hafiz Lathe Machines

Pengerjaan material dengan Turning lathe machine atau Mesin bubut teknologi operasional bisa dilakukan sesuai dengan tipenya yang manual, semi-auto maupun full CNC.. Boring mill lathe; adalah mesin bubut yang memiliki rangka vertikal dan benda kerja diletakkan pada chuck atau alat cekam lain yang menghadap ke atas. Boring mill lathe ini.