Type 7100 Precision Air Pressure Regulator ControlAir

Selecting a pressure regulator can be a complex process that first requires a general understanding of how a pressure regulator works. A regulator's main purpose is to maintain a constant pressure on one side of the regulator even though there is a different pressure or fluctuating pressure on the other side. The primary reason for regulating.

What is a Pressure Regulator and the Difference Between Various Types? F95ZONEUS

Learn about EPRs and EEPRs and how they control pressure and temperature in the evaporator. Because of the vast array of products that must be safely refrige.

what is a pressure regulator My Engineering

A line pressure regulator is a gas pressure regulator intended for installation in a building gas distribution system between the building service regulator or LP‐gas 2, 5, and 10 PSIG service regulator and gas utilization equipment.. ANSI Z21.80/CSA 6.22 is the standard for line pressure regulators suitable for operation with natural, manufactured, and mixed gases, liquid petroleum gases.

Type 7000 Precision Air Pressure Regulator ControlAir

The major purpose of a regulator is to match the flow of the medium which could be gas, steam, or liquid through the regulator according to the requirement of the medium for the system. It would keep the system pressure at the required pressure and thus would control the overpressure and it would prevent the problems which could occur in the.

Fuel Pressure Regulator Pengertian, Fungsi, Cara Kerja, Kerusakan Moservice.id

The accuracy of a pressure regulator is determined by charting outlet pressure versus flow rate. The resulting graph shows the drop in outlet pressure as the flow rate increases. This phenomenon is known as droop. Pressure regulator accuracy is defined as how much droop the device exhibits over a range of flows; less droop equals greater accuracy.

Pressure regulator Pneumatic Pressure Control valve

Pressure regulator merupakan salah satu komponen dari sistem bahan bakar injeksi EFI. Fungsi dari pressure regulator adalah untuk mengatur tekanan bahan bakar yang mengalir ke injektor. Banyak sedikitnya bahan bakar yang diinjeksikan ke dalam ruang bakar dikontrol sesuai dengan lamanya signal yang diberikan ke injektor, sehingga tekanan yang.

SHININGEYES Air Pressure Regulator 1/4 NPT with Gauge 0145 PSI tillescenter Compressed Air

These types of regulators are commonly spring-loaded and are available in both back-pressure and pressure-reducing designs. They should also be sensitive to adjustment, allowing operators to achieve the specific pressures they need with minimal effort. Some features to look for include: Fine-pitched threads on the stem of the control spring.

Pressure Regulators White Knight Fluid Handling

Pressure control regulators, valves, and valve systems are essential to safe and consistent pressure and flow control and fluid measurement. Emerson provides pressure and flow control solutions to applications in energy production, aerospace, semiconductor fabrication, chemical engineering and other industries.

Pressure Regulator Ultra High Delivery Model GP 8700 Hydracheck

Pressure Reducing Regulators A pressure reducing regulator maintains a desired reduced outlet pressure while providing the required fluid flow to satisfy a downstream demand. The pressure which the regulator maintains is the outlet pressure setting (setpoint) of the regulator. Types of Pressure Reducing Regulators This section describes the.

How Do Gas Pressure Regulators Work for Industrial Processes?

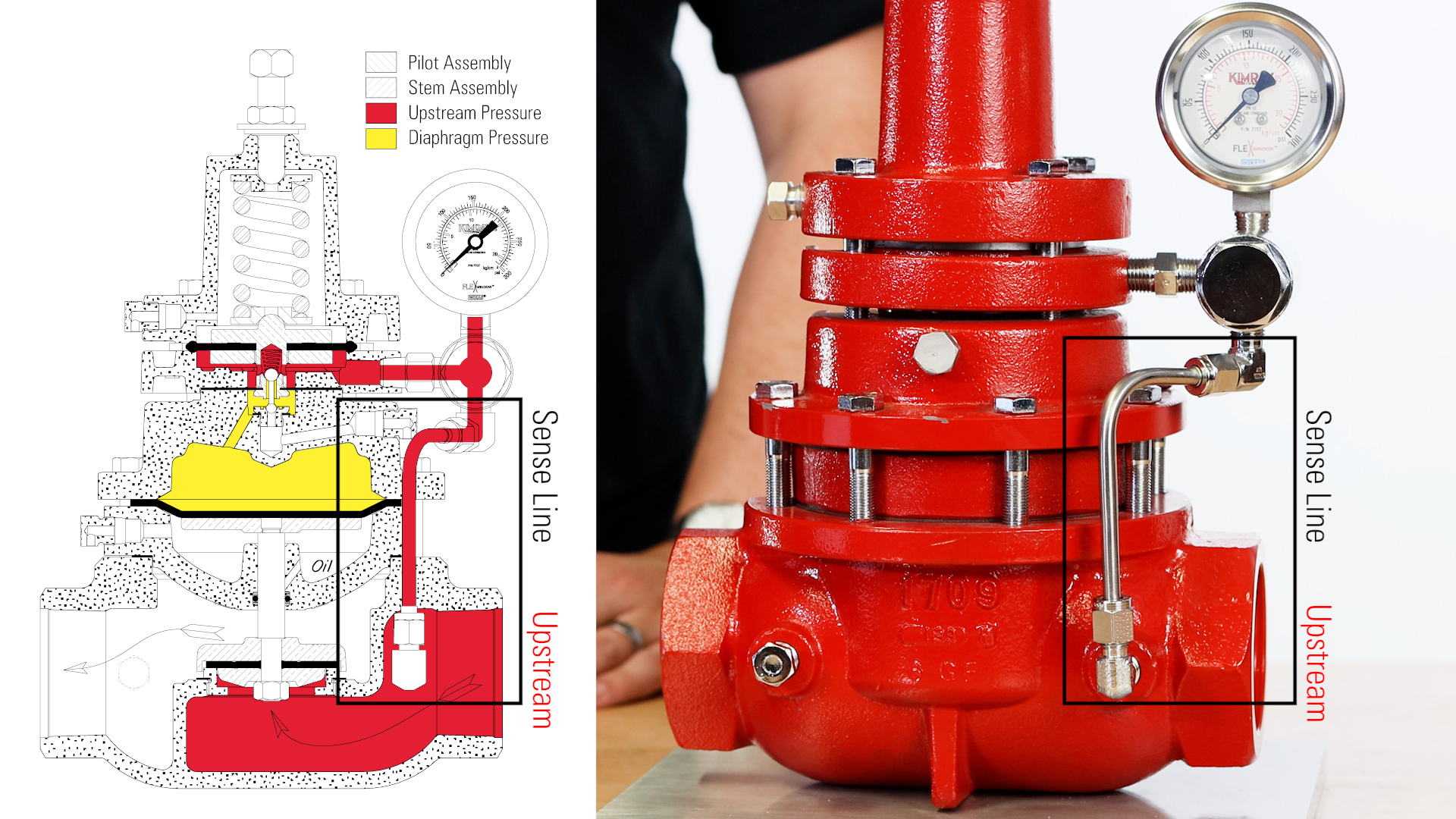

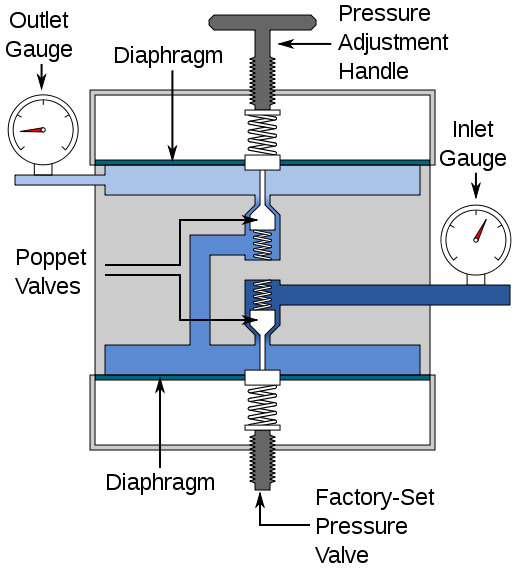

Inside, a water pressure regulator has a variable spring-loaded diaphragm that automatically widens and narrows depending on the amount of water pressure entering the valve. When the water enters the regulator at high pressure, the inner mechanism constricts the diaphragm to narrow the flow of water. This can reduce the pressure into a range of.

Air pressure regulators basics purpose, working principle, and more FAQ ShopTransmitter

Definisi Pressure Regulator. Pressure Regulator adalah katup mekanis yang menggunakan umpan balik untuk mengontrol tekanan dalam sistem pneumatik dan hidrolik. Pada dasarnya ada dua jenis regulator: satu mengatur tekanan hulu (regulator tekanan balik) dan yang lainnya mengatur tekanan hilir (regulator penurun tekanan)..

Pressure Regulator vs. Backpressure Regulator PlastOMatic Valves, Inc.

In this case, the liquid will take 25 minutes to travel through 3 meters (approximately 10 feet) of 6 mm (1/4 in.) tubing. To reduce this time, we must reduce the volume of the tubing preceding the regulator. For example, with only 30.5 cm (1 ft.) of 3.2 mm (1/8 in.) tubing, it would take only 30 seconds for the liquid to reach the regulator.

MAXITROL Gas Pressure Regulator, NPT, 1250000 BtuH 490N423257L (11/4") Grainger

Pressure regulators reduce a supply (or inlet) pressure to a lower outlet pressure and work to maintain this outlet pressure despite luctuations in the inlet pressure. The reduction of the inlet pressure to a lower outlet pressure is the key characteristic of pressure regulators. When choosing a pressure regulator many factors must be considered.

Type 100 Precision Air Pressure Regulator ControlAir

It was originally published Nov. 15, 2002. RELATED. Pressure regulators, more commonly known as pressure-reducing valves, keep the output pressure constant in compressed-air systems no matter how.

How Do Gas Pressure Regulators Work?

A pressure regulator is a valve that controls the pressure of a fluid to a desired value, using negative feedback from the controlled pressure. Regulators are used for gases and liquids, and can be an integral device with a pressure setting, a restrictor and a sensor all in the one body, or consist of a separate pressure sensor, controller and.

Pressure regulator for nozzle SB with pressure gauge, ø10mm pushin fittings and mounting

Differential pressure regulating valve. Differential pressure regulators are built into the system where a constant differential pressure is desired. They are often installed at the connection point between a district heating system and a consumer building. This ensures that there is a constant differential pressure available for the building.