Reamer , its parts and their types Informational Encyclopedia

Straight reamer adalah reamer yang paling umum digunakan hanya untuk membuat sedikit pembesaran lubang pada bahan seperti perunggu, kuningan, dan besi tuang. 5. Shell Reamer. Shell reamer adalah alat yang dirancang tanpa shank dan memiliki lubang di tengahnya, digunakan untuk proses reaming bearing dan operasi serupa lainnya. Saat operasi.

free shipping 2pcs/lot reamer 1/8 " reamer 1/4" with straight shank each 1 pcs. in Reamer from

Yang pertama dari sisi ukuran, versi aftermarket tentu lebih beragam, tinggal pilih saja sesuai kebutuhan. "Kalau TB standar reamer ada maksimalnya, kalau TB aftermarket kan banyak varian ukuran. Udah gitu misal beli TB aftermarket 40 mm, masih bisa di- reamer lebih besar lagi," sahut Ergus Oei dari R59 Racing.

Apa Itu Reamer dan Apa Saja Sih Fungsinya?

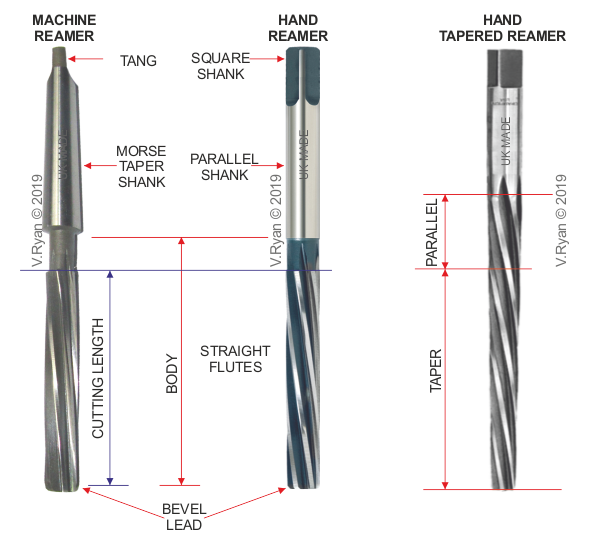

These are the main types of reamers: Chucking Reamers are the most widely used reamer and commonly used in lathes to enlarge smooth holes. Morse Taper Reamers are used to finish morse taper holes or sleeves. Automotive Reamers are used to ream steel for car parts such as steering arms, ball joints, and tie rod ends in vehicles.

Combination Reamer, For Drilling & Reaming, Multicut Carbide Tools Private Limited ID 4800314312

This article will discuss the 14 types of reamer tools used in machining, their specific purposes, and how to use them. 1. Carbide Reamers. Carbide materials (Tungsten-carbide, Titanium-carbide, and Tantalum-carbide) are among the hardest materials that can be manufactured at scale. Reaming tools are also the main application for cermets, the.

What is Reamer 9 Types of Reamer Tools with Applications

Pengertian Reamer dan Fungsinya. Apa itu reamer dan apa saja fungsinya? Reamer adalah suatu proses untuk membuat karburator menjadi lebih lebar agar ada ruang lebih bagi udara saat lewat. Pada bagian pilot dan main jet harus diawasi saat proses reamer dilakukan pada karburator. Dua bagian tersebut harus diatur sedemikian rupa agar saat proses.

Custom Reamer Manufacturer Gammons Hoaglund

Summary. Reamers are an integral part of deepwater Gulf of Mexico (GOM) drilling and their performance significantly impacts the economics of well construction. This paper presents a novel programmatic approach to model rate of penetration (ROP) for reamers and improve drilling efficiency. Three field implementations demonstrate value added by the reamer drilling optimization (RDO) methodology.

mechanical engineering Reamer and its types

A reamer is a tool used to smooth out or make an existing hole larger. Reamers are not drill bits, and they are not used to create holes. Instead, you will use the reamer inside the hole to smooth it out or enlarge it ever so slightly. Reamers are made to be used on different types of materials, and there are many options available.

Types of Reamers and Their Uses [with Pictures] Engineering Learner

generally, shell reamers are suitable for larger holes, often greater than ¾". Their convenient design makes them cheaper than other reamer tools and allows flexibility for engineers. 5. Hand Reamers. A hand reamer is designed for manual reaming, as opposed to a machine reamer, which is used on machine tools.

Reamer Basics YouTube

Endodontic files and reamers are surgical instruments used by dentists when performing root canal treatment.These tools are used to clean and shape the root canal, with the concept being to perform complete chemomechanical debridement of the root canal to the length of the apical foramen.Preparing the canal in this way facilitates the chemical disinfection to a satisfactory length but also.

REAMERS AN INTRODUCTION

Follow the manufacturer's guidelines here, but a good rule of thumb is to drill the hole approximately 3% smaller than the finished hole. For instance, a 1/8" diameter reamed hole should be drilled with a #31 drill bit (0.12"), whereas a 3/4" reamer would require either a 47/64" (0.734") or 18.5 mm (0.728") starter hole.

Reamer Part2 YouTube

The surface finish obtainable when reaming generally depends on the workpiece material. The range for cast iron is 50 to 80 rms and 30 to 60 rms for steels, and a PCD reamer can impart a finish as fine as 8 rms in aluminum, according to Bysterbusch. Sometimes a hole is bored prior to reaming, but that's not mandatory.

Expert HSS Adjustable Reamer Set 15/32 1 1/2 Chronos Engineering Supplies

Fungsi Reamer atau Proses Reaming Adalah. Reaming adalah untuk menghasilkan diameter lubang bor yang sesuai dengan hasil dari penggalian mata bor (bit). Alat untuk proses reaming ini disebut reamer, itulah fungsi reamer. Hal ini disebabkan karena sepanjang aktivitas pemboran mungkin akan terjalin penyempitan lubang bor akibat swelling formation.

Reamers Lomas Engineering Cutting Tools

Bahan keras yang paling umum adalah tungsten carbide (padat atau berujung), tetapi reamers dengan tepi kubik boron nitrida (CBN) atau berlian juga ada. Perbedaan utama antara kedua kategori adalah bahwa material keras biasanya tidak terpengaruh oleh panas yang dihasilkan oleh proses pemesinan dan mungkin benar-benar mendapat manfaat darinya.

PCD reamers offer long tool life and productivity gains while reducing secondary operations

A reamer is a type of rotary cutting tool mostly used in metalworking. A reamer is a tool used for expanding or finishing pre-drilled holes, bored, or cored to give a good finish and an exact dimension. The reamer is intended to be used in a drill press, turret lathe. Reamer is also used in the screw-cutting machine.

Jual Reamer Terbaik Untuk Industri LFC

A reamer tool is a precision cutting instrument employed in metalworking, woodworking, and various machining applications. Its primary function is to create accurately sized and smooth holes, typically in cylindrical or conical shapes. Reamers are essential in achieving high levels of precision and quality in hole-making processes.

Reamer Solid Carbide Reamer Accusharp Reamer tools to fulfil your Industrial needs. Accusharp

Using reamer bits offers several benefits, including: 1. Precision: Reamer bits allow for precise hole enlargement, ensuring accurate dimensions and proper fitment of components. 2. Versatility: With various types and sizes available, reamer bits can be used for a wide range of applications and materials. 3.